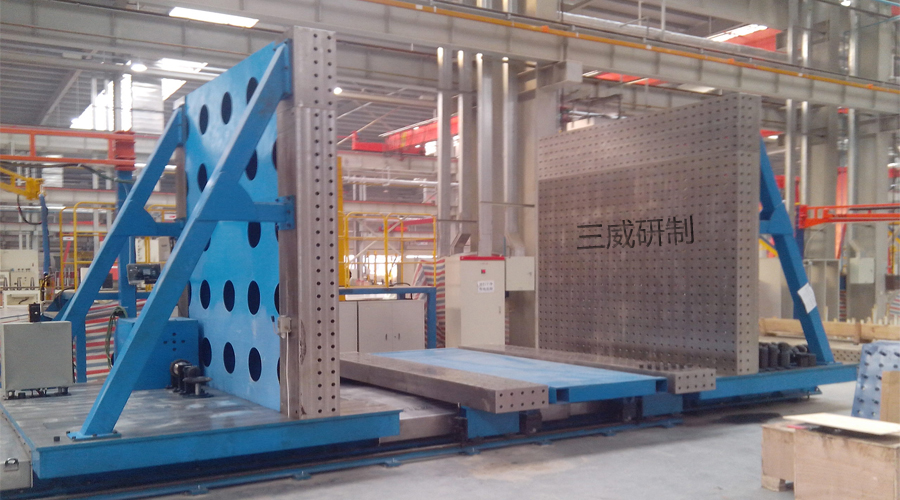

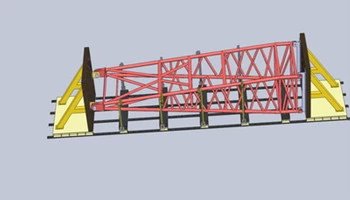

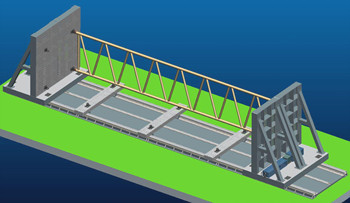

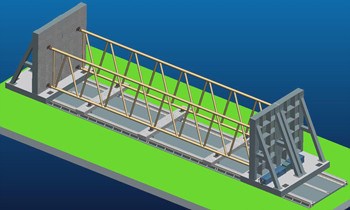

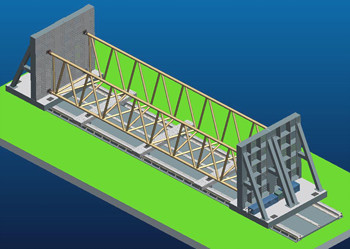

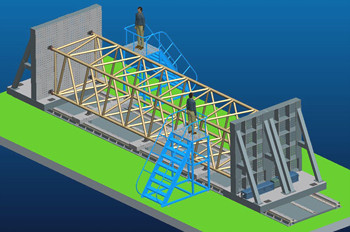

2. Introduction of welding tooling for section arm truss

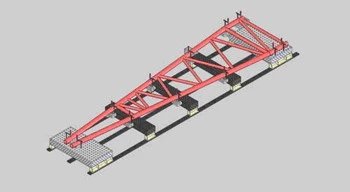

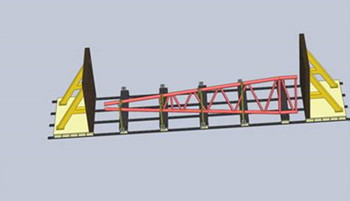

The welding fixture of the section arm truss is 20 meters long, 3 meters wide and 3 meters high. It consists of left and right positioning bent plates (fixed backing and movable backing), basic rails, fine-tuning mechanism, intermediate auxiliary support U-shaped square box, V-shaped support block assembly, male and female joint connection seat, positioning pin, quick locking pin, (with compensation screw) clamp, etc. In addition to the advantages of the general three-dimensional welding combined fixture system, this fixture also has the following characteristics:

(1) High flexibility. The tooling can meet the welding of any standard length boom and truss with a maximum cross-section of 2800x2800mm. The tooling can be quickly interchanged by simply replacing the corresponding male and female connectors. At the same time, the positioning section can be expanded by connecting auxiliary parts on the three sides to meet the positioning welding of the boom truss with larger cross-section sizes.

(2) High precision. Each component module of the tooling system has high processing accuracy. The flatness error of the 4-meter-long and 2-meter-wide working platform is within 0.15mm, the position error of the positioning hole is within ±0.05, and the verticality and parallelism of the fixture support surface are 0.05/1000mm.

(3) Repeatability. Using the CAD design system, it is very convenient to simulate the assembly of samples. The precise module size ensures assembly accuracy and saves product development time and cost.

3. Application of flexible combination tooling

The boom truss is an important part of crawler cranes. The largest lifting tonnage in China is 4,200 tons. There are more than a dozen specifications ranging from 50 tons to 4,200 tons. Due to market needs, the arm lengths of cranes vary, so each specification of boom extension boom usually has four specifications of 3, 6, 9 and 12 meters. In addition to the number of upper and lower booms, the general manufacturer has dozens or even hundreds of boom varieties. Although there are many sizes and specifications, their appearances are completely similar. If the company makes a set of corresponding welding positioning tooling for each specification during the production process of the boom truss, you can imagine how huge the investment in process equipment is. If this set of tooling is available, a large amount of tooling cost investment can be saved, including the cost of tooling site occupation. The tooling has been widely used in engineering machinery companies such as Sany, XCMG, Liugong, Yutong, and Foton Lovol Heavy Industry.

The process flow of welding the boom (truss) on this tooling is as follows:

Mia Liu

Mia Liu 400 004 8480

400 004 8480