Modular clamp holding system

Individuality begins with the selection of the table series and size. The combination of the worktop, table legs and surface hardness completes your personal worktable. Select the matching accessory set and configure your new SANWZB 3D welding table and clamping system for your individual application.

Individuality begins with the selection of the table series and size. The combination of the worktop, table legs and surface hardness completes your personal worktable. Select the matching accessory set and configure your new SANWZB 3D welding table and clamping system for your individual application.System Hole Welding Table |

|||||||||||||||||||||||

|

System hole D28 / D22 / D16 |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

3D Welding table |

2D Welding table |

||||||||||||||||||||||

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

Quilateral 3D welding table |

Octaagonal 3D welding table |

Quilateral 2D welding table |

Octaagonal 2D welding table |

||||||||||||||||||||

SANWZB is committed to producing the world's finest welding and fixture tables. We have taken our proprietary material, machining, and hardening processes to the next level with a new standard in table hardness and toughness. The unsurpassed technical excellence of SANWZB tables is complemented by a wide range of mounting options and improved fixture accessories with new features such as hardened finishes, numbered scales, and rounded edges. | Declaration | 28 SYSTEM | 22 SYSTEM | 16 SYSTEM | ||

Borehole Ø (mm) | 28 | 22 | 16 | |||

Borehole spacing (mm) | 100 | 100 | 50 | |||

Borehole spacing(Table side panel) (mm) | 50 | 50 | 25 | |||

Grid spacing (mm) | 100 | 100 | 50 | |||

Table side panel (mm) | 200 | 150 | 100 | |||

Material thickness (mm) | 24 | 18 | 12 |

◎ D28 system Welding Table ◎ |

◎ D22 system Welding Table ◎ |

◎ D16 system Welding Table ◎ |

|||||||||

|

|

|

|||||||||

For large welded constructions Suitable for light to heavy parts, Can realize the infinite possibilities of the workpiece group pair. |

For light and medium-duty applications suitable for medium components. Meet your different usage scenarios and habit preferences. |

For delicate applications Suitable for light and small (Seiko) components. Among the three system holes, the D16 system is the correct choice of fine structural parts | |||||||||

| ▪ Welding table system hole grid | ||||||||||||||||||||||

| For D28/D22 System hole: | For D16 System hole: | |||||||||||||||||||||

| ① Standard grid:100 x 100 (mm) Code: B | ① Standard grid:50 x 50 (mm) Code: B | |||||||||||||||||||||

| ② Diagonal grid 100 x 100 (mm) Code: X | ② Diagonal grid 50 x 50 (mm) Code: X | |||||||||||||||||||||

| ▪ About product

code Full coding of products: SWK□□-□□□□□-□□ SWK■■-■■■■■-□□ ■■■■■■■ - Product identification ID Example: 2810005 - D28 hole system, 2000x1000x200 (mm) 3 D steel welding table ※ SW - SANWEI company K - System Hole 1)SWK■■-□□□□□-□□ ■■ - System Hole Size.(28 - 28 System hole / 22 - 22 System hole / 16 - 16 System hole ) 2)SWK□□-■□□□□-□□ ■ - Product Large Category Code.(The Arabic numerals, 1-9)

|

||||||||||||||||||||||

| 4)SWK□□-□□■□□-□□ ■ - Material

identification code.(The Arabic numerals, 0-9) 0 - steel, 1 - Cast Iron, 2 - 304 stainless steel, 3 - Ductile iron, 4 - Aluminium, 5 - Nonmetal 5)SWK□□-□□□■■-□□ ■■ - Product Serial Number.(The Arabic numerals, 01-99) |

||||||||||||||||||||||

| 6)SWK□□-□□□□□-■□ ■ - System Hole Grid code: B - Standard grid, X - Diagonal grid | ||||||||||||||||||||||

| 7)SWK□□-□□□□□-□■ ■ - Surface Processing code.(The Arabic numerals, 0-4) 0 - Painting, 1 - Blackening, 2 - Nitriding, 3 - Hardened tool steel Nitriding,4 - Hard Chrome plating |

||||||||||||||||||||||

| Description of the

surface treatment code of the welding table (The last two digits of the

product code,SWK□□-□□□□□-■■ ): |

||||||||||||||||||||||

| B0 - Standard grid,Painting on non-working surface(or Color of the material) | X0 - Diagonal grid,Painting on non-working surface(or Color of the material) | |||||||||||||||||||||

| B1 - Standard grid,Surface:(Phosphating)Blackening | X1 - Diagonal grid,Surface:(Phosphating)Blackening | |||||||||||||||||||||

| B2 - Standard grid,Surface:Plasma Nitride | X2 - Diagonal grid,Surface:Plasma Nitride | |||||||||||||||||||||

| B3 - Standard grid,Surface: Plasma Nitride(Hardened tool steel) | X3 - Diagonal grid,Surface: Plasma Nitride(Hardened tool steel) | |||||||||||||||||||||

| B4 - Standard grid,Surface:Hard Chrome plating | X4 - Diagonal grid,Surface:Hard Chrome plating | |||||||||||||||||||||

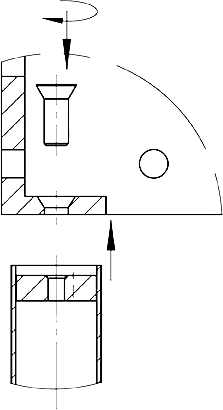

| The welding table is

supplied with standard legs. The extremely sold design ensures very high

load-bearing capacity – 3,000 kg per leg. |

|

||||

|

Easy and secure mounting of the table leg to the welding table |  |

± 30 mm fine adjustable |

||

|

|

|

|||

|

|

|

|

|

|

|||||||||

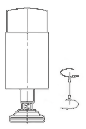

| Square Leg | Round Leg | Telescoping leg | Leg for spacer block | Holding Frame | Scissor Lift | |||||||||

| Table legs > | ||||||||||||||

|

|

|

|

|

|

|

||||||||

| Protective Spray | Bench Stone | Pump Bottle | Ball end hex wrench | Brush | Ground Connector | Assembly lever | ||||||||

|

|

|

|

|||||||||||

| Torque wrench | Burner Holder | Transport ring | Accessory cart | |||||||||||

| Table accessories > | ||||||||||||||

Follow us

Mia Liu

Mia Liu 400 004 8480

400 004 8480