Modular clamp holding system

Industry

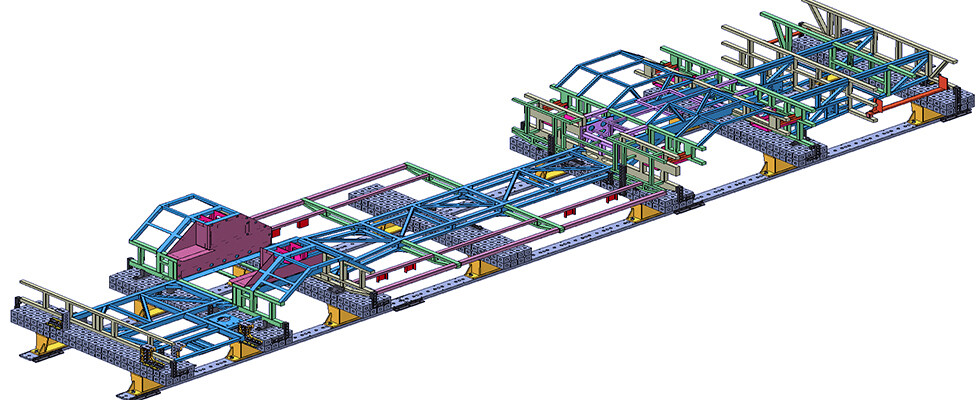

Innovation: Full Load-Bearing Bus Frame Flexible Welding Fixtures

CRRC Times Electric Vehicle Co., Ltd.

was the first to introduce the 3D flexible modular fixture system from Dongguan Sanwei Company, achieving excellent results and setting an example for flexible welding production of new energy buses in the industry. Zhejiang CRRC has also adopted a complete set of 3D flexible welding fixture systems developed and manufactured by our company for their welding production line.

Product

Structure as the Basis and Process Capability as the Guarantee

Currently, the bus industry is characterized by custom production, small batches, and personalization, with increasing demands for vehicle quality. Bus companies must enhance their process capabilities to improve product quality, production efficiency, and reduce costs. The improvement of whole vehicle manufacturing process capabilities will largely determine the future development of new energy bus enterprises.

The main processes include stamping, welding, painting, and final assembly (including chassis assembly). Without scientific and reasonable process methods, high-quality bus products cannot be achieved, and thus client recognition and value cannot be attained.

The

second phase project of CRRC Times Electric involves a total investment of 300

million yuan, with an additional construction area of nearly 30,000 square

meters. The main construction includes a new chassis assembly workshop, a new

painting electrophoresis workshop, the renovation of the existing combined

workshop (used as the body workshop), the expansion of the sewage treatment

plant, charging station, public station, and the purchase of advanced

production and testing equipment. This aims to improve and optimize the current

process level, enhance the quality of new energy bus products, and expand the

influence of the CRRC Times Electric brand.

Full

Load-Bearing Frame and Flexible Welding

It is well known that the full load-bearing frame, made of rectangular tubes, is one of the most recognized safe structural technologies. However, controlling deformation during welding and quickly changing the frame type has been a challenge in the manufacturing of new energy buses. With the characteristics of custom production, small batches, and personalization, bus companies must enhance their process capabilities to improve product quality, production efficiency, and reduce costs. The enhancement of whole vehicle manufacturing process capabilities will largely determine the future development of new energy bus enterprises.

A top-notch vehicle manufacturing process and an advanced 3D flexible modular welding fixture system are prerequisites for manufacturers of new energy buses to provide high-quality products. This full load-bearing electric vehicle frame flexible welding fixture system is used for assembling and welding the load-bearing frame, meeting the production needs of multiple products with a single set of flexible fixtures. It ensures welding precision and deformation control while enabling quick switching between different models, creating a unique industry advantage. Utilizing a flexible welding production line allows for rapid response to customer demands and adaptation to different orders. It can timely and maximally meet market order changes, providing customers with diverse choices.

The

3D flexible modular welding fixture system particularly demonstrates its

advantages in the production of special vehicles, engineering vehicles, and

large buses in small batches. Using flexible fixtures for welding production is

an economical and practical method.

Analysis

of China's Automotive Manufacturing Industry

China's continuous economic growth has accelerated the development of the automotive manufacturing, engineering machinery, and shipbuilding industries. According to data from the China Industrial Association, in 2007, China's automobile production and sales both exceeded 8.8 million units, with a year-on-year growth of 22.02%, making China the second-largest automobile consumer country after the United States. It is expected that automobile sales could reach 15 million units by 2015. The production of special vehicles is moving towards small batches and diversification. The costs and manufacturing cycles of specialized automotive molds and fixtures put tremendous pressure on production units. Thus, flexible modular fixtures have become the inevitable choice for manufacturing enterprises, reducing matching cycles and production costs. CRRC Times Electric is the first domestic unit to successfully apply a flexible modular fixture system to the welding of full load-bearing electric vehicle chassis frames, developed and provided by Dongguan Sanwei Equipment, achieving excellent results and setting an example for flexible welding production of new energy buses in the industry.

Before 2002, domestic mold enterprises mainly produced molds for trucks and box trucks, while car molds were only at the level of producing structural component molds. Welding fixture enterprises were limited to producing sub-welding fixtures and component assembly fixtures for internal parts. From 2003 to 2007, domestic mold enterprises gradually began producing complete car body molds, and welding fixture enterprises acquired the capability to produce from chassis assembly to complete car body main welding lines, approaching international advanced levels in key technologies.

Internationally, some advanced companies have high-level welding development capabilities and have formed a pattern with a few companies having advanced vehicle welding process platforms at the core, and many highly specialized small and medium-sized welding fixture companies as a collaborative network. Major automotive companies like Toyota in Japan, Volkswagen in Germany, Peugeot in France, and General Motors in the US have been using 3D digital process planning and simulation software for nearly ten years. Domestically, there is still a lack of unified digital information management methods for high-volume, highly automated welding line process planning, and no capability has yet been formed for planning such high-automation welding lines.

As China transitions from "Made in China" to "Created in China," more Chinese flexible modular fixture brands will be recognized worldwide, especially Dongguan Sanwei Equipment. The 3D flexible modular fixture industry, as a driving force supporting automotive development, is full of vitality and, with the spirit of national industry, will inevitably go global and achieve brilliance!

Follow us

Mia Liu

Mia Liu 400 004 8480

400 004 8480