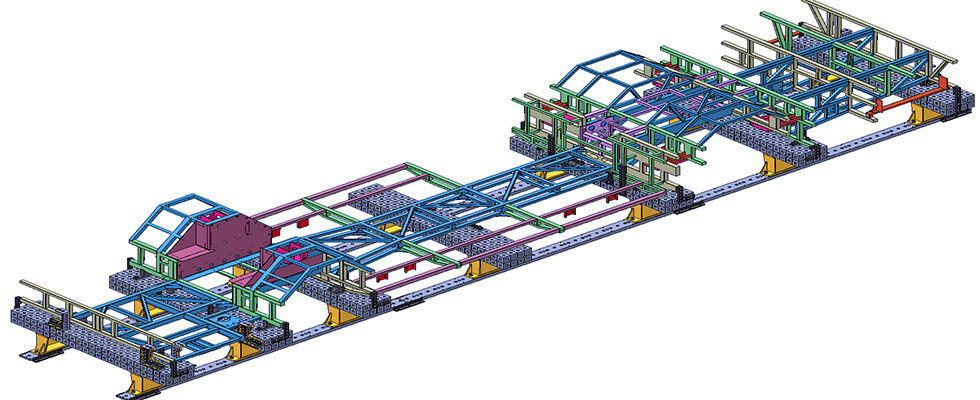

Modular clamp holding system

Currently, most full load-bearing frames of new energy electric vehicles are made of welded rectangular tubes, which is one of the most recognized safe structural technologies.

However, controlling deformation during welding and quickly switching frame types have always been challenging in the manufacturing of new energy buses.

Moreover, with the increasing number of customized vehicles being ordered, traditional specialized fixtures can no longer adapt to model changes.

Therefore, adopting multifunctional 3D flexible welding fixtures has become an inevitable trend.

Characteristics

of the Bus Industry

The bus industry is characterized by custom production, small batches, and personalization, with increasing demands for vehicle quality. Bus companies must enhance their process capabilities to improve product quality, production efficiency, and reduce costs. The improvement of whole vehicle manufacturing process capabilities will largely determine the future development of new energy bus enterprises.

The main processes include stamping, welding, painting, and final assembly (including chassis assembly). Each step requires scientific and reasonable process methods to meet high-quality production standards and fulfill customized client demands. Without this, high-quality bus products cannot be achieved, nor can client recognition and value be attained.

A top-notch vehicle manufacturing process and an advanced 3D flexible modular welding fixture system are prerequisites for manufacturers of new energy buses to provide high-quality products. This flexible welding fixture system for full load-bearing electric vehicle frames meets the production needs of multiple products with a single set of fixtures. It ensures welding precision and deformation control while enabling quick switching between different models, creating a unique industry advantage. Utilizing a flexible welding production line allows for rapid response to customer demands, adaptation to different orders, and maximally meets market changes, providing customers with diverse choices.

Advantages of 3D

Flexible Modular Welding Fixtures

The 3D flexible modular welding fixture system is particularly advantageous in the production of special vehicles, engineering vehicles, and large buses in small batches. Using flexible fixtures for welding production is an economical and practical method.

Analysis of Full

Load-Bearing Electric Vehicle Frame Welding Manufacturing in China

From a mechanical perspective, low-end large buses use truck-like flexible frames. The upper layer cabin and lower axle leaf springs are rigid, and the flexible frame in the middle acts as a crucial buffer layer besides bearing all loads. High-end large buses feature rigid frames without the flexible middle layer, forming a two-layer structure where the rigid chassis and body constitute a rigid whole, bearing the vehicle's entire load. CRRC Times Electric is the first domestic company to successfully apply a flexible modular fixture system to the welding of full load-bearing electric vehicle chassis frames, developed and provided by Dongguan Sanwei Equipment, achieving excellent results and setting an example in the industry.

Characteristics of Load-Bearing Bus Body

Structures

The full load-bearing body structure's chassis is a grid structure made of rectangular tubes, not the traditional stamped and riveted frame structure. This chassis, along with the front and rear ends, side panels, and roof, forms the full load-bearing body. The body uses a closed loop structure, lowering the floor and overall vehicle height. The entire body participates in load-bearing, achieving stability and balance under load. The grid structure chassis, with high torsional rigidity, ensures the normal working relationship of assemblies like the engine and axles.

Advantages:

- Reduced body

weight

- Improved

structural strength and rigidity

- Simplified

component forming process and improved material utilization

- Lower vehicle

center of gravity and better high-speed stability

- No need for

large stamping equipment, facilitating model changes and multi-variety

production

- Superior passive safety, ensuring passenger safety during rollovers and collisions according to European bus passive safety tests

Bus Body

Assembly and Welding Equipment

Full load-bearing body welding must be done on fixtures to control relative positions and dimensions, effectively control welding shrinkage, and improve efficiency. Fixtures generally consist of a clamping body, positioning unit, and clamping unit. The clamping body can be cast or welded from sections. Rectangular tubes, with small section size tolerances, are mostly used for positioning blocks. Manual, pneumatic, and hydraulic clamping devices are used, each with advantages and drawbacks.

Large assembly fixtures are often interchangeable, allowing the production of different wheelbases and suspensions with adjustments. Mass production companies use translational assembly fixtures, while high-end bus manufacturers use hydraulic flipping and lifting fixtures for accurate positioning and reduced secondary positioning errors. CO2 gas shielded welding is commonly used, with some high-end companies using argon and CO2 mixed gas shielded welding for better welding quality.

Internationally, advanced companies use 3D digital process planning and simulation software and form networks of specialized welding fixture companies around core enterprises with advanced vehicle welding platforms. Domestically, there is a lack of unified digital information management for high-volume, highly automated welding lines, and the capability for planning such lines is not yet established.

As China transitions from "Made in China" to "Created in China,"

More Chinese flexible modular fixture brands, especially Dongguan SANWZB, will be recognized globally. The 3D flexible modular fixture industry, with a spirit of national industry, will inevitably go global and achieve brilliance.

CRRC Times Electric Vehicle Co., Ltd. was the first to introduce the 3D flexible modular fixture system from Dongguan Sanwei Company, achieving excellent results and setting an example for flexible welding production of new energy buses in the industry.

Zhejiang CRRC has also adopted a complete set of 3D flexible welding fixture systems developed and manufactured by our company for their welding production line.

Follow us

Mia Liu

Mia Liu 400 004 8480

400 004 8480